For different materials, the machine software can store 9 cycle settings for heating and cooling process, enabling consistent high-quality results.

- WhatsApp: +86 13606526028

- Email: contact@utien.com

FMQP-1200/2

Utien has developed a brand new welding system to help weld banners which are made of PVC and other plastic sealable materials. The banner welding machine is based on electrical impulse heating technology which saves power and offers good stable sealing quality. The machine is CE certified and several safety protection systems are built on the machine to protect the operator.

It’s an impulse heat welding machine. The machine requires no warm up time and seals by applying a pulse of energy to the sealing area, followed immediately by cooling. It’s able to make the union of various plastic fabrics such as screen, PVC tarpaulin, banner, and more.

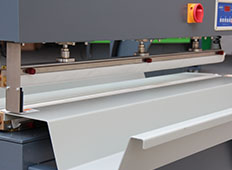

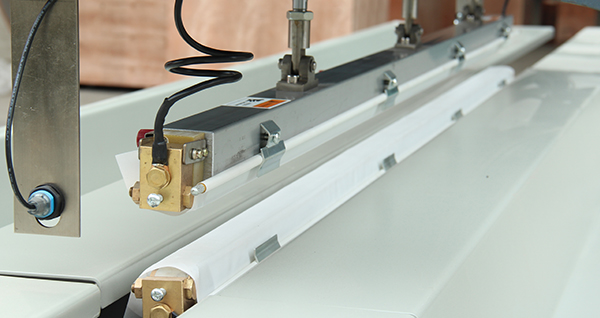

1. The machine adopts horizontal sealing, with the cylinder as the pressing power, so that the sealing pressure can be adjusted steadily, suitable for the sealing requirements of different materials.

2. Heating up and down at the same time (instantaneously), with high power, firm sealing, no wrinkles and clear pattern.

3. The heating time and cooling time are controlled by a single-chip microcomputer, and the time is accurately adjustable.

4. 9 groups of formula parameters can be stored, can be recalled at any time according to the packaging requirements of different products.

5. The welding length is 1200-5000mm, and special specifications can be customized.

| Machine Parameters | |

| Machine Model | FMQP-1200/2 |

| Sealing Length | 1200mm |

| Sealing Width | 25mm |

| Compress air requirement | 0.5 MPa |

| Power | 1.2kW |

| Voltage | 220V / 50Hz |

| Dimensions | 1370mm×570mm×1350mm |

| Weight | 120kg |

For different materials, the machine software can store 9 cycle settings for heating and cooling process, enabling consistent high-quality results.

Heat only exists during sealing time.

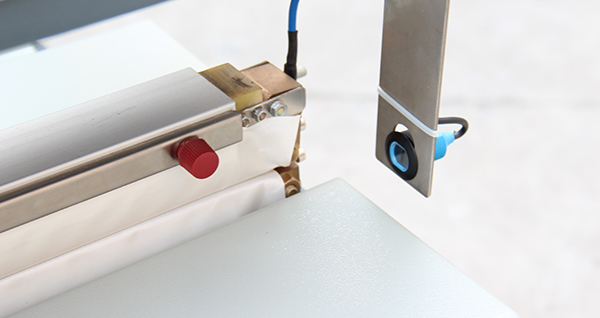

Laser sensor ensures no hands are present in work plate during machine operation.

Double sealing steps maximize the prevention of accidents during machine operation.

Pneumatic sealing bar keeps average pressure on sealing material, which makes the sealing seam smooth and strong. The power is stronger with double sealing bars.

By continuing to use the site you agree to our privacy policy Terms and Conditions.