Copyright © 2019 Utien Pack Co.,Ltd. All rights reserved. Site Map

- WhatsApp: +86 13606526028

- Email: contact@utien.com

Utien specializes in advanced tray sealing machines specifically designed for the food industry. These machines are capable of handling various packaging methods, including sealing with options for modified atmosphere packaging (MAP) and vacuum skin packaging (VSP). This capbility allows them to efficiently seal food products in pre-formed trays, which helps to extend shelf life and maintain product freshness. Our product line includes both semi-automatic and fully automatic food tray sealers tailored to fit specific production requirements and integrate seamlessly into existing setups.

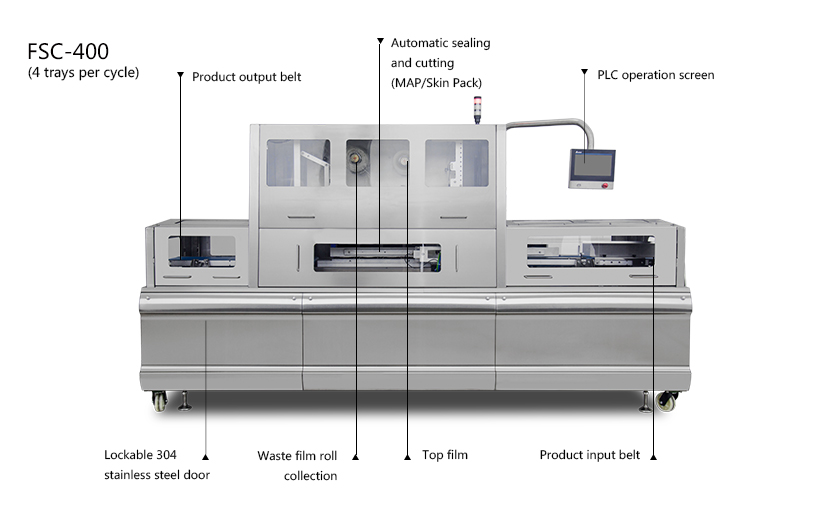

Our FSC series automatic continuous tray sealer is suitable for almost all types of trays and materials. Different printing materials are available for the cover film, which are used for MAP packs and VSP packs, depending on the packaged product and needs. This tray sealer is constructed of Sani-safe stainless steel and is easy to load and operate or integrate into your processing line with its conveyor system to deliver superior yield and lower production costs.

FSC-400 Continuous Tray Sealer Machine can meet the packaging needs of large-scale production. With a professionally designed tray feeding mechanism, it can run continuously, significantly enhancing packaging efficiency. Based on varying packaging requirements, multiple sets of mold is optional for different products. Utien offers comprehensive and specialized packaging solutions tailored to client specifications.

Our semi automatic tray sealers FG-040 are designed to pack and seal prefabricated trays and are the perfect solution for small and medium-sized, batch, efficient and economical packaging. Also it’s an ideal entry-level devices for tray packaging. With MAP and VSP packaging option, this equipment is able to cover various top films onto trays of different materials.

The FSC-600 Automatic Continuous Tray Sealer is tailored for large production environments, capable of sealing 6 trays per cycle, significantly increasing productivity. It features an advanced tray feeding system for continuous operation, making it ideal for businesses with high-volume packaging demands.

As a leading tray sealing machine manufacturer, Utien ensures our machines are adept at handling a diverse array of food types with ease. Our seal packaging machines are crafted for simplicity of use, empowering businesses to boost their production efficiency. From small-scale manual tray sealers to high-speed automatic tray sealing machines, our solutions are designed to boost productivity, enhance food quality, and ensure a secure seal for prepared meals, ready-to-eat products, frozen foods, and more.

Utien's advanced tray sealers are not only designed for long-term durability but also feature the ability to provide high-quality and flexible sealing solutions. All these functions ensure that food production is always fast, precise, and safe.

• Variety of tray sealer sizes depending on production needs

• 30 Years of experience in packaging & production

• All products are manufactured with ISO9001:2008 standards

Selecting the best tray sealer depends on various factors, such as production scale, tray material, and specific packaging requirements. Our experts are here to assist you in choosing the perfect industrial tray sealing equipments, whether it’s a compact manual tray sealer for small batches or a fully automated system for high-volume production lines. We also provide customizable options to ensure that your machine fits seamlessly with your production processes. Whether you need a solution for food packaging, medical packaging, or industrial applications, we offer a variety of tray sealers to suit your needs. Contact us via info@utien.com today for your custom packaging solutions.

A: Tray sealers, also known as tray lidding machines, heat sealers, or top sealers, are incredibly versatile packaging equipments. They are adept at affixing plastic film lids to trays made from different materials, accommodating a range of sizes and depths. This flexibility makes them an ideal packaging solution for a multitude of applications.

A: Tray sealers automate the packaging process by precisely placing product-filled trays into position, where they are then sealed with a top film through a heat sealing method. The machine applies heat and pressure to bond the film to the tray, creating an airtight seal that preserves the contents. After sealing, the excess film is trimmed, and the sealed trays are ejected for further processing.

A: A tray sealer machine comprises an in-feed conveyor for tray alignment, a sealing film dispenser, a heated sealing plate for bonding the film to the tray, a cutting device for trimming excess film, and an out-feed system to dispatch the sealed packages, all managed by a central control panel and often supplemented with vacuum and gas flush systems for modified atmosphere packaging.

A: Choosing the right tray sealing equipment for your business depends on your production needs. For high-speed, high-volume production environments, our FSC 400/600 model, an automatic tray sealer, is ideal as it offers efficient, continuous operation. If your needs are more modest or your volume is lower, our FG 020/040 model, a semi-automatic tray sealer, provides a more suitable, cost-effective solution. Each option ensures reliability and quality sealing for a range of tray packaging requirements.

A: Yes, our tray sealers are compatible with a variety of materials including PE, PS, C-PET, A-PET, EPP, EPET, and PP, allowing you to choose the best material for your product and sustainability goals.

A: Our food sealing machines, featuring Modified Atmosphere Packaging (MAP) technologies, significantly extend the shelf life of food products. Equipped with MAP, our meal tray sealers are particularly valuable for businesses looking to reduce spoilage costs, enhance food safety, and distribute their products over longer distances, ensuring fresher, safer food reaches consumers.

A: Tray sealing preserves food shape and is ideal for ready-to-eat meals, while vacuum sealing compresses products. Compare tray sealing and vacuum sealing method to decide which suits your needs.

By continuing to use the site you agree to our privacy policy Terms and Conditions.