Usually, the capacity is usually 6-8 circles/min.All features controlled by servomotor with high speed and precision.

- WhatsApp: +86 13606526028

- Email: contact@utien.com

FSC-400

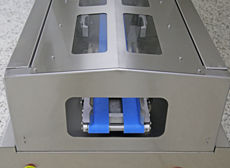

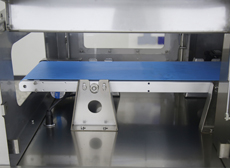

FSC-400 Continuous Tray Sealer Machine can meet the packaging needs of large-scale production. With a professionally designed tray feeding mechanism, it can run continuously, significantly enhancing packaging efficiency. Based on varying packaging requirements, multiple sets of mold is optional for different products. Utien offers comprehensive and specialized packaging solutions tailored to client specifications.

1. Packing speed: 6-8 cycles/min

2. Packaging option: MAP, VSP and Simply Sealing

3. High speed, high precision and accurate control with servo motor

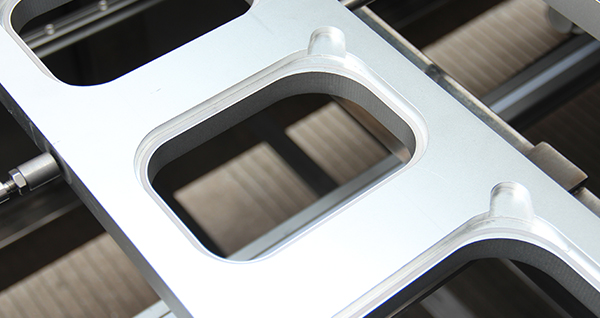

4. Multiple sets of molds can be customized

5. Workable with various top roll films

6. Uses German Busch vacuum pumps, with oxygen residual below 0.4%.

7. Utien's unique skin pack technology (Unifresh®) ensures outstanding packaging results.

8. The machine body is made of 304 stainless steel, which is corrosion-resistant and easy to clean.

| Machine dimension(mm) | 3410×1121×1857 |

Speed(cycles/min) Cycles/min, Top Seal Cycles/min, MAP Cycles/min, Skin Pack | 10~12 6~8 6~8 |

| External diameter of the film roll(mm) | ≤300 |

| Power(kW) | 15 |

| Vacuum Pump | BUSCH |

| Power voltage(V/Hz) | 380/50 or Customized |

| Oxygen residual for MAP | ≤0.4% |

| Gas option | N2,CO2/N2, O2/CO2/N2 |

| Top film | Transparent top film, pre-printed top film |

| Packaging applications | Fresh foods, cooked foods, seafoods, frozen products, ready meals, fruits and vagetables... |

Usually, the capacity is usually 6-8 circles/min.All features controlled by servomotor with high speed and precision.

Attractive package with top VSP(UniFresh ®) technology. With top Busch vacuum, we can make residual oxygen lower than 1%.

Applied to trays of various shapes and sizes

By continuing to use the site you agree to our privacy policy Terms and Conditions.