Two independent vacuum chambers work in turn, allowing for continuous packaging without interruptions. Ideal for high-volume production environments where speed and efficiency are critical.

- WhatsApp: +86 13606526028

- Email: contact@utien.com

Our Commercial Double Chamber Vacuum Packaging Machine has two vacuum chambers which can work in turn. When the product is packaged in the first chamber, the second chamber can unload the packaged product and put on the unpacked product again. In this way, the double chamber vacuum sealer can archive high efficiency packaging process.

The whole machine is made of food grade stainless steel, is easy to clean and corrosion resistant.

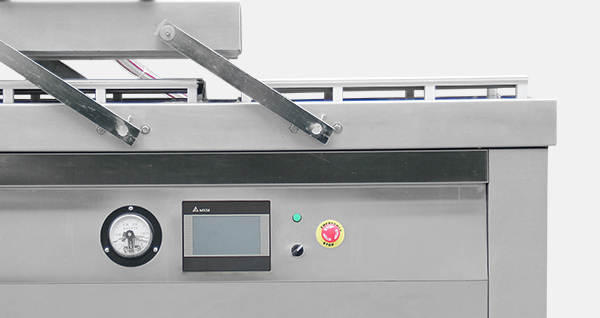

Vacuum and sealing are completed at one time, with PLC touch screen operation, vacuum time, sealing time and cooling time can be adjusted accurately.

Two vacuum chambers work in turn, with high production efficiency and high speed.

It’s compact & reliable, with wide application.

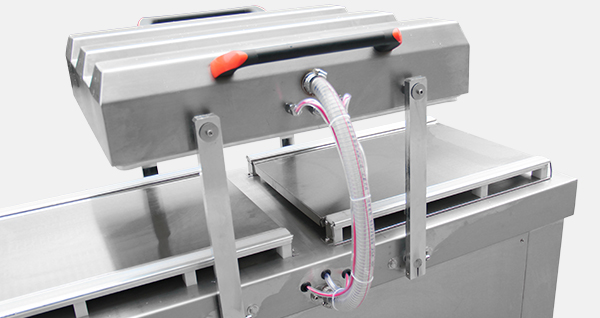

There are two types of sealing methods: pneumatic sealing and air bag sealing. The conventional model is air bag sealing.

Double chamber vacuum sealer is an ideal solution for companies who want to boost their packaging operations without sacrificing floor space. With four sealing bars and two sealing chambers, this product will quickly package small, medium and large size products and immensely increase shipping efficiency in shorter time.

DZ-500 features 304 stainless steel construction with two 20-inch seal bar located in each chamber provides the option of sealing four large chamber pouches at once or doubling up of smaller bags for maximum efficiency. A powerful commercial-grade, 1.55 hp oil pump delivers a quick and quality vacuum in 20-30 seconds. Smooth-rolling caster wheels allow the Utien DZ-500/2S Double Chamber Vacuum Sealer to be moved easily for cleaning or maintenance.

High efficiency vacuum packing can be carried out through two chambers.Utien double chamber vacuum packaging machine has two vacuum chambers which can work in turn. When the product is packaged in the first chamber, the second chamber can unload the packaged product and put on the unpacked product again. In this way, the double chamber vacuum packaging machine can achieve high efficiency packaging process comparing to Single Chamber Vacuum Packaging Machine.

It's easy for you to set the vacuum, seal, and cool time throught control panel. Bag locks on the seal bar gasket reduce bag movement during busy production cycles. The Utien double chamber vacuum packaging machine is perfect for small-medium volumn processors needing to package large size products like meat, sauce, flavouring, dry fruits and bean products. It's also a solution for large catering companies and hotels that need to package large quantities of food for events.

This machine is mainly suitable for products that require vacuum packaging in the food industry, meat, grains, soy products, snack foods, preserved fruits, pickled products, medicinal particles, solids, etc., and can prevent oxidation, mildew, rot, and moisture to extend the storage or preservation period of the product.

| Machine Parameters | |

| Machine Model | DZ-500/2S |

| Sealing Length | 500mm×2 |

| Sealing Width | 10mm |

| Maximun Vacuum | ≤-0.1MPa |

| Voultage | 380V / 50Hz |

| Power | 2.3kW |

| Chamber | 500mm×420mm×95mm (19.7" x 16.5" x 3.7") |

| Dimensions | 1250mm×760mm×950mm (49.2" x 29.9" x 37.4") |

| Weight | 220kg |

Two independent vacuum chambers work in turn, allowing for continuous packaging without interruptions. Ideal for high-volume production environments where speed and efficiency are critical.

Made from 304 stainless steel, the machine is corrosion-resistant, durable, and easy to clean, making it perfect for food processing industries.

Equipped with an advanced PLC touch screen control panel, operators can easily adjust vacuum time, sealing time, and cooling time for precise packaging results.

Q: What is the difference between single chamber and double chamber vacuum sealers?

A: Double chamber vacuum sealers offer higher efficiency by allowing continuous operation. While one chamber is sealing, the other can be loaded, reducing downtime.

Q: Can this machine handle large-sized products?

A: Yes, the DZ-500 features 500mm sealing bars and a spacious chamber, making it suitable for large-sized products.

Q: Is the machine easy to clean?

A: Absolutely! The stainless steel construction and removable components make cleaning quick and hassle-free.

By continuing to use the site you agree to our privacy policy Terms and Conditions.