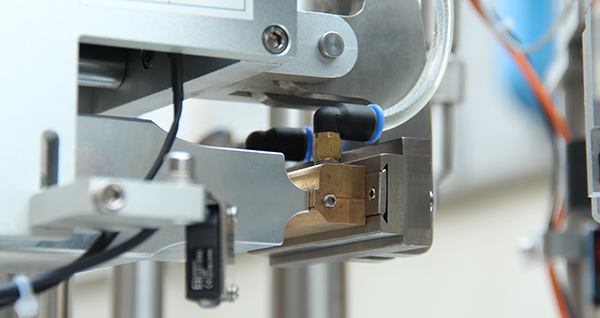

Top tube welding technology

Plastic molecules are strongly jointed together with ultrasonic power, firm and nice welding regardless of cream remaining on tubes.

Ultrasonic Tube Sealing Machine

The DGF Ultrasonic Tube Sealing Machine utilizes advanced ultrasonic wave technology to fuse molecules on tube surfaces through ultrasonic friction, ensuring strong and clean seals. This method prevents weak welding caused by foreign matter and offers superior sealing with date and batch printing. Key functions include tube loading, orientation, filling, sealing, cutting, and unloading, making it efficient for various packaging needs.

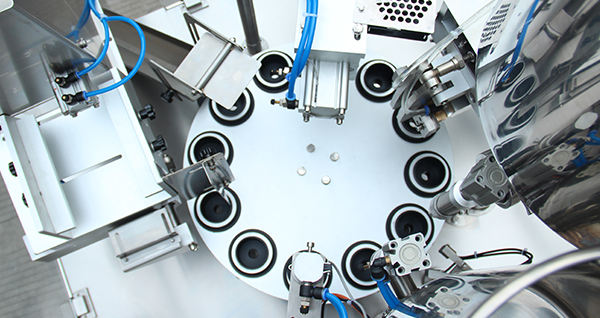

The design of the ultrasonic tube sealers mainly takes into account the production requirements of some users for batch tube sealing. The appearance is simple and beautiful, the volume is small and convenient to move. At the same time, it integrates with auto tube loading, position turning, filling, sealing edge cutting and output in one efficient sealing machine

The workbench adopts the structure of the disc rotary table, which can make the overall process more efficient and reasonable. The whole machine is made of stainless steel, is easy to clean and without stains. It is a necessary machine for cosmetics and other industries.

1. PLC control system with simple operation.

2. The ultrasonic frequency has advanced scanning successively and automatic correction function.

3. With automatic error alarm function.

4. Adopting the new type of automatic tube loading mechanism, the loading is smooth without jamming.

| Machine Parameters | |

| Capacity | 0-25PCS/min |

| Control | PLC control |

| Frame material | 304 SUS |

| Mold material | 6016 Aluminium |

| Dimensions | 900mm×800mm×1650mm |

| Weight | 400-500kg |

| Tube | |

| Sealing Widths | 3-8(Customizable) |

| Sealing Length | <85mm (Diameter<50mm) |

| Tube length | <200mm |

| Filling volume | <200lm |

| Material | PP |

| Filling product | liquid or half liquid |

| Components | |

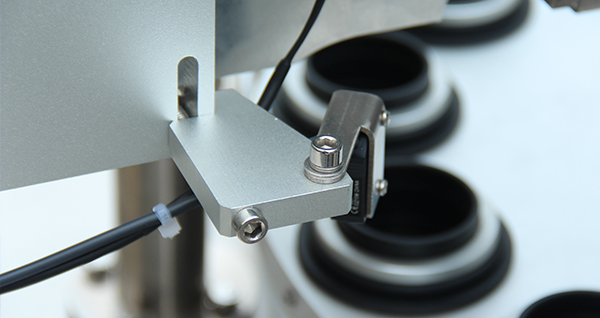

| Japan SMC pneumatic parts | French Schneider electrical parts |

| Auto frequency tracker | Taiwan DELTA servo motor and PLC control units |

| Power | |

| Electric | 220V/50Hz |

| Pneumatic | 0.4-0.8 MPa |

Plastic molecules are strongly jointed together with ultrasonic power, firm and nice welding regardless of cream remaining on tubes.

To ensure working efficiency, we apply high quality aluminum alloy to make the rotary table and tube base. Such design is durable and decent and easy to maintain.

User-friendly operating screen, easy control with finger touch.

With ability to track and adjust the frequency of ultrasonic wave, we ensure every stable sealing result.

By continuing to use the site you agree to our privacy policy Terms and Conditions.