Unifresh® Skin Pack

Patented technology for protruding products up to 50 mm, ensuring strong seals and premium shelf appeal.

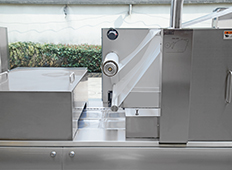

RC-VSP Series

Utien Thermoforming Vacuum Skin Packaging (VSP) Machine integrates a fully automated process—from forming, filling (manual or automatic), sealing, and cutting, to final product output. The system uses a rigid bottom film, which is heated and stretched to form a tray. The product is placed inside, then a top skin film is applied and vacuum-sealed tightly around the product surface like a second skin.

The vacuum skin packaging process ensures minimal residual oxygen and provides additional benefits, including but not limited to leak-proof protection through self-liquid retention, microbial growth delay by limiting oxygen exposure, vertical display capability for enhanced retail presentation.

The VSP technology is ideal for fresh and processed meat, fish, poultry, cheese, pates, and ready meals. By combining advanced thermoforming technology and high-vacuum sealing, Utien delivers safe, efficient, and premium food packaging solutions.

Vacuum Skin Packaging (VSP) uses a high-vacuum process to tightly seal a heat-softened top film over the product and a pre-formed rigid or flexible tray—creating an airtight “second skin” that locks in freshness and enhances visual appeal. The RC-VSP series integrated with VSP technology to

1. Enhance product presentation for premium shelf impact

2. Provide strong tray-like support for protection and structure

3. Enable vertical display without product shifting

4. Extend product shelf life through oxygen removal

5. Retain liquids and gases to prevent spoilage

6. Support customized mold and equipment options

7. Support top lid application for labeling or branding

8. Create space for promotions (recipes, spoons, etc.) between films

9. Offer easy-open materials through custom film design

| Machine Parameters | |

| Speed | 6-8Cycles/min |

| Forming Depth | ≤50mm |

| Film widths | ≤520mm |

| Advance Length | ≤500mm |

| Bottom Film | |

| Material | Sealable PE/PA Multi-layer Co-extruded Plastic Film |

| Unprinted Color Bottom Film or Transparent Film | |

| Roll Diameter | 500mm |

| Thickness | ≥300um |

| Top Film | |

| Material | Sealable PE/PA Multi-layer Co-extruded Plastic Film |

| Pre-printed Top Film or Transparent Top Film | |

| Roll Diameter | 250mm at most |

| Thickness | ≤200um |

| Components | |

| Vacuum Pump | BUSCH(Germany) |

| Electrical Components | Schneider(French) |

| Pneumatic Components | SMC(Japanese) |

| PLC Touch Screen & Servo Motor | Inovance(China) |

| Machine Parameters | |

| Dimensions | 6000mm×1300mm×1870mm |

| Weight | 2000kg |

| Working Height | 1000mm |

| Loading Area Length | 1500mm(Customizable) |

Patented technology for protruding products up to 50 mm, ensuring strong seals and premium shelf appeal.

Protrusion Technology

Quick mold swaps minimize downtime and increase output.

Self-developed cutting technology ensures smooth edges, no “fish-hook” effect, premium look.

Keeps products fresh up to 3× longer, reducing waste and boosting sales.

Up to 3 Times Longer

Shelf Life

Patented forming technology reduces film use by 20–25%, lowering costs per pack.

Up to 25%

Film Thickness

Servo-driven system delivers consistent seals and longer tool life.

We deliver packaging line solutions through the integration of advanced equipment and intelligent auxiliary units—engineered to achieve maximum efficiency and precision.

Multihead weigher

Online labeller

Injet printer or thermo transfer printer

Auto filling syste

By continuing to use the site you agree to our privacy policy Terms and Conditions.