- WhatsApp: +86 13606526028

- Email: contact@utien.com

Thermoforming is a process, which consists in the fact that the moulding of products is carried out not from the melt, but from blanks of polymer material (sheet, film) heated to a softened state.

There are several types of thermoforming: vacuum forming, pneumoforming, pneumatic vacuum forming, free drawing with a punch, or stamping, etc.

All these varieties are united by a fundamental commonality of technologies, the essence of which is as follows:

· A polymer blank is heated to softening

· By applied force, it is formed into a shape

· Then the forming shape is cooled

Basic methods of thermoforming

The implementation of thermoforming methods is quite simple.

A sheet or film polymer blank is heated to a temperature of a highly elastic state.

Then, by deforming it in various ways, the latter is given the necessary shape, which is fixed by cooling the moulded product.

Depending on the method of creating the driving force of the process of deformation of the work piece into a finished product, the following methods of thermoforming of plastics are distinguished.

· Vacuum

· Pneumatic

· Hydraulic

· Mechanical

· Combined.

Vacuum forming:

The workpiece takes its final shape under the influence of atmospheric pressure (1 atm = 0.1 N / mm2), therefore this method is most preferable for thin-walled products.

· Initially, the workpiece is pressed along the perimeter to the working chamber of the vacuum forming machine by a clamping frame over the technological forming tooling.

· Then, using a heating device, they are heated to a highly elastic state and the workpiece is stretched.

· Then, in the cavity formed by the surfaces of the workpiece and the forming matrix (or forming punch), a vacuum is created, as a result of which, due to the resulting pressure drop, the plasticized workpiece is pressed against the forming tool under external air pressure and the product is formed.

· After cooling the product to the temperature of its dimensional stability, it is removed from the forming tool, after opening the pressure frame.

The advantage of vacuum forming is that thin-walled moulded parts with a large surface area can be produced using simple tools.

The technology of vacuum forming allows the production of parts with low or large seriality with moderate costs, significantly reduced than with injection moulding.

Pneumatic moulding

The processes of pneumatic moulding differs from vacuum moulding only in that the pressure drop is created by using compressed gas as a working medium,which often has an excess pressure of up to 2.5 Mpa.

Therefore, if the thickness of the blanks to be formed is more than 5 mm or to obtain products with high accuracy, it is recommended to use pneumatic moulding, since the material is pressed against the forming tool by high pressure (from 7 bar = 0.7 N / mm2 to 10 bar = 1 N / mm2).

Hydraulic Forming

In hydraulic forming, the role of the working medium is played by the heated liquid, which is injected by the pump under a pressure of 0.15–2.5 MPa.

Mechanical Moulding

Mechanical moulding (mechanothermoforming) differs from pneumatic moulding processes in that a flat heated blank is shaped into a finished product due to its mechanical drawing with a metal punch.

Combination

Modern production technologies also provide for the combination of different methods of moulding products, for example, pneumatic vacuum, pneumatic mechanical, etc.

Please note that if the final product involves the implementation of a fine structure or the presence of a small volumetric pattern, then it is recommended to use blanks with a thickness of less than 5 mm.

The indisputable advantages of the thermoforming method include:

· The simplicity of the technology and machine design

· Low energy consumption

· Low cost of the equipment used,

· The possibility of higher automation

· Versatility in the type of recyclable plastics, with a simplified transition from one polymer material to another.

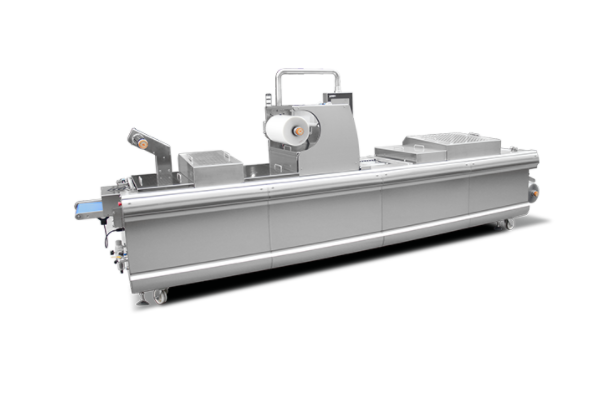

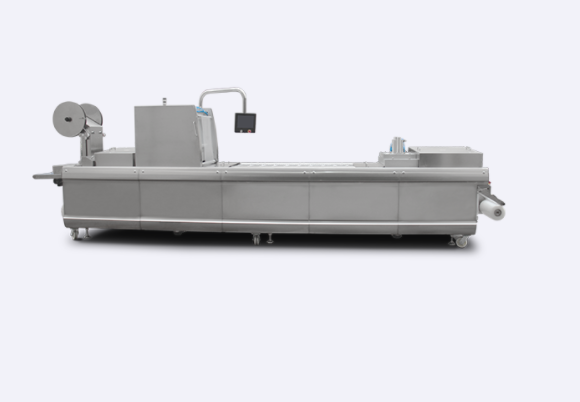

In need of a thermoforming packaging machine?

We manufacture all our product with the simple goal to yield the best result for our customers. Take a chance with us and make a purchase you can’t regret.

Kindly contact us to purchase one of our world-acclaimed thermoforming packaging machines.

By continuing to use the site you agree to our privacy policy Terms and Conditions.