- WhatsApp: +86 13606526028

- Email: contact@utien.com

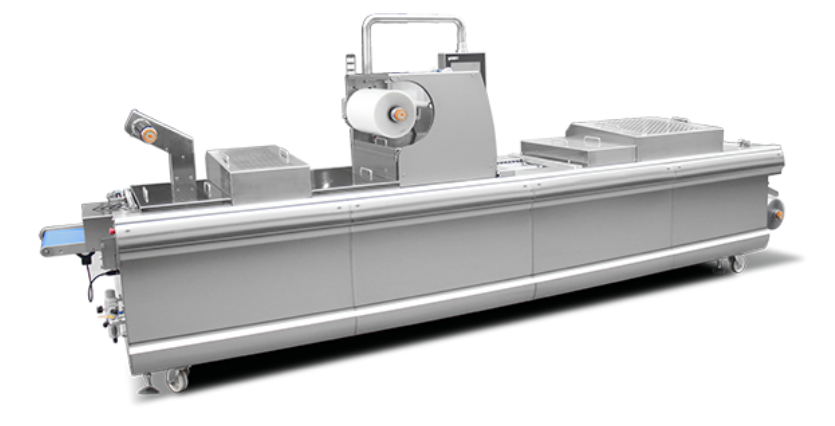

If you own an Industry that is involved in packaging products into plastic sheets or aluminum foil, then certainly you should know that having a well designed Thermoforming Vacuum Packaging Machine is of great help.

Thermoforming Vacuum Packaging Machine renders the service of heating a thermoplastic sheet to its softening point. The sheet is then cooled into the desired shape and dimension that suits the application.

Thermoforming generally involves the transformation of a plastic sheet into a 3-dimensional shape through the application of heat, vacuum, and pressure.

Thermoforming Vacuum Packaging Machines have several benefits and applications in various manufacturing industries.

In this article, we will walk you through the benefits and applications of Thermoforming Vacuum Packaging Machines as well as the materials used in Thermoforming.

Materials processed by Thermoforming Vacuum Packaging Machines

Not all materials can be processed by Thermoforming Vacuum Packaging Machines. However, this machine can specifically be used in processing a large number of materials.

Such as:

Soft and flexible, PP is able to be thermoformed into various shapes. It has been widely applied in food and household industries with high temperature resistance and chemical resistance.)

This material can be easily fabricated. It occurs in a clear form and it is resistant to wear and tear. Several colors of Acrylics are also available.

This material is specifically resistant to chemical corrosion. It is also stable at low temperatures. Nevertheless, its stability is not as reliable as those of other materials.

This material is brittle but forms easily. It is relatively cheaper than other materials that are used in thermoforming. It is also available in several colors.

This material is also resistant to both chemical corrosion and abrasion. It is used most times for making bottles and for replacement of medical joints.

This thermoforming material is used for many purposes. It can withstand stress and pressure to a great extent. It is also resistant to chemicals. Several textures and colors are available.

There are various benefits associated with using a Thermoforming Vacuum Packaging Machine to process several materials.

l It allows for the detection of errors in design and fit issues before it is too late.

l It saves money, time and energy.

l It can be used for processing both small and large materials.

l It is highly efficient

l It is cheap to maintain.

l It is easy to add details.

The thermoforming Vacuum Packaging Machines can be applied in several ways.

Some of the most common ones include the following:

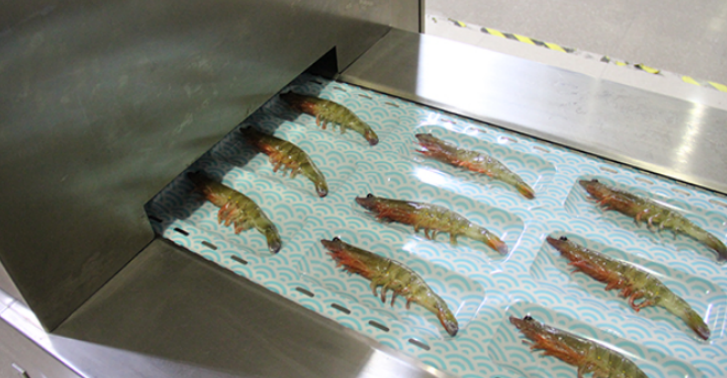

Packaging of retail clamshells.

Packaging of blisters.

Packaging of pick and place trays

Packaging of trays and covering materials.

Shipping trays packaging

packaging of medical equipment

Pop displays

Are you in need of high quality Thermoforming packaging equipment for several industrial applications? But wait... Seems you are skeptical about getting a reputable Supplier.

Worry no more, we got you covered. With us, you are assured of getting high quality Thermoforming Vacuum Packaging Machines with integrity. Click here to view our products.

By continuing to use the site you agree to our privacy policy Terms and Conditions.