- WhatsApp: +86 13606526028

- Email: contact@utien.com

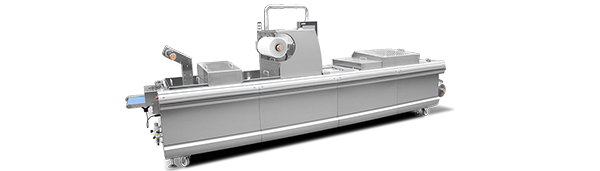

Most of the plastic industry employs a thermoforming packaging machine in a thermoforming process to manufacture different molds of plastic.

It is a process that involves the heating up of plastic to a high temperature and then poured into a mold to cool and form. The mold determines the shape of the plastic sheet is physically in touch with it. After this, the mold is usually cut to fit into the desired product.

Also, there are many unique features of the thermoforming process, including the intricacies in the mold, the nature of finishes required, the materials employed, and the mold type whether male or female. The materials used for this process are plastic sheets obtained from high-density Polyethylene, Polycarbonate, Polypropylene, etc. These materials are of high quality and durable to guarantee a long life span of usage.

Thermoforming has a lot of advantages over other ways in the manufacturing of plastic products such as injection and rotational molding.

There are two outstanding advantages for using a thermoforming method for plastic products which are a low cost of production and extremely high turnaround times. These make them ideal for the production of customized plastic products of not large quantities.

Other benefits of thermoforming process over the other methods are as follows:

1. Low cost of tooling largely due to the number of molds required which is one mold and a half.

2. Easy to operate, full touch screen control, friendly interface, convenient and quick mold replacement and body maintenance.

3. A broader design is achievable from the prototype development

4. Extremely high speed for just –in –time production design

5. Ease of material and process optimization for profitability

6. Improvement of products during the process of production

7. The packaging is of excellent quality and can be customized to a high degree. The appearance, shape, size, etc. can be customized.

8. Quality after-sales service, solutions are provided within 24 hours, and repairs can be made to the factory within 48 hours.

Applications of thermoforming Packaging machine

Thermoforming packaging machines are used in various industries, such as meat products, fresh fruits and vegetables, medical equipment and other non-food machinery.

Due to the rapid spread of the epidemic at home and abroad last year, Utien's thermoforming packaging machine also contributed to this. Provide packaging solutions for domestic and foreign consumers to ensure that all medical-related devices are dust-free, sterile, and pollution-free. The main contributions are: saline bag packaging, medical gauze packaging, syringe thermoforming packaging and so on.

In need of a high-quality thermoforming packaging machine

The thermoforming packaging machine is vital equipment with several benefits to exploit in various industries. However, sourcing for genuine and quality one can sometimes be a difficult task, hence the need for partnership with a reliable and trusted thermoforming packaging machine manufacturer.

Utien Pack Co., Ltd is one of the few globally recognized enterprise known for manufacturing high-quality plastic products. We have high tech and skillful professionals who use quality materials to build a thermoforming packaging machine. You can contact us to make your choice today!

By continuing to use the site you agree to our privacy policy Terms and Conditions.