- WhatsApp: +86 13606526028

- Email: contact@utien.com

Different from heat sealer, ultrasonic tube sealers use ultrasonic technology to enable molecules on the surface of the tubes to be fused together by ultrasonic friction. It combines auto tube loading, position correcting, filling, sealing and cutting. What's more, it makes fast and less space occupied. It is also the perfect choice for cosmetic cream or other cream product tube filling and sealing. Its technology is a perfect solution for cosmetic or other liquid/semi-liquid product tube sealing.

Ultrasonic Welding

1. Definition

Ultrasonic welding has become a well-accepted method for joining high-volume, relatively small plastic parts. In this process, an ultrasonic generator is used to produce oscillations of one substrate against a stationary second substrate. This, in turn, causes intense frictional heating between the two substrates, which is sufficient to rapidly generate a molten weld zone. With pressure and subsequent cooling, a strong bond can be obtained.

2. Process

The ultrasonic welding process consists of four phases.

In phase 1, the horn is placed in contact with the substrate, pressure is applied, and vibratory motion is started. Heat generation due to friction melts points of direct contact, and the molten material flows into the joint interface.

In phase 2, the melting rate increases, resulting in increased weld displacement, and the part surfaces fully meet.

In phase 3, steady-state melting occurs, as a constant melt layer thickness is maintained in the weld.

In phase 4, the holding phase, the vibration ceases, maximum displacement is reached, and a high joint strength occurs as the weld cools and solidifies.

3. Application

Ultrasonic welding is suitable both for welding of plastics and metals. Plastic is a pretty poor conductor of heat and can't dissipate the heat before it changes the state of the plastic from solid to liquid. With a bit of pressure applied, this makes the two parts blend together as if they are a single piece of plastic. Once the ultrasonic signal is stopped, the parts become solid again. This is the magic that creates a clean and strong weld between two parts.

What ultrasonic tube sealer can Utien provide?

· DGF-25C Ultrasonic Tube Sealers

1. Advantage

Ultrasonic wave technology enables molecules on the surface area of the tubes to be fused together by ultrasonic friction.

Ultrasonic welding avoids the disadvantages that weak welding causes due to foreign matter adhering to the tube walls.

Ultrasonic provides superior and attractive sealing including date and batch printing.

2. Core Technology

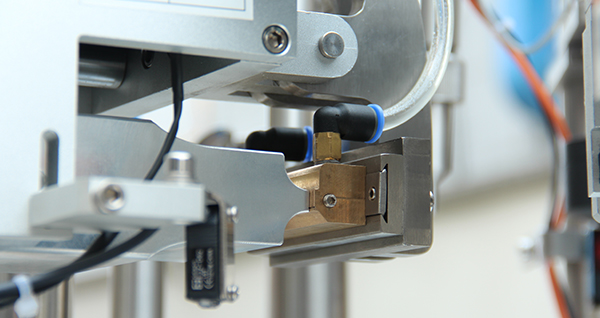

· Top tube welding technology

Plastic molecules are strongly jointed together with ultrasonic power, firm and nice welding regardless of cream remaining on tubes.

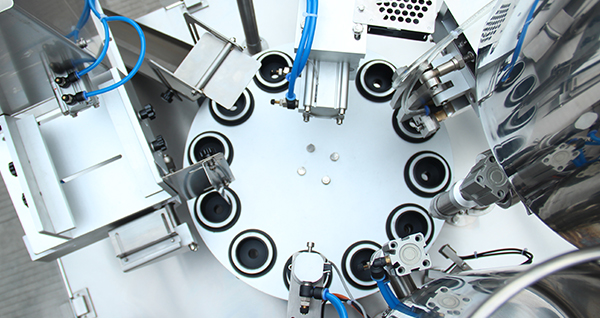

· Rotary working process

To ensure working efficiency, we apply high quality aluminum alloy to make the rotary table and tube base. Such design is durable, decent and easy to maintain.

· PLC control system

User-friendly operating screen, easy control with finger touch.

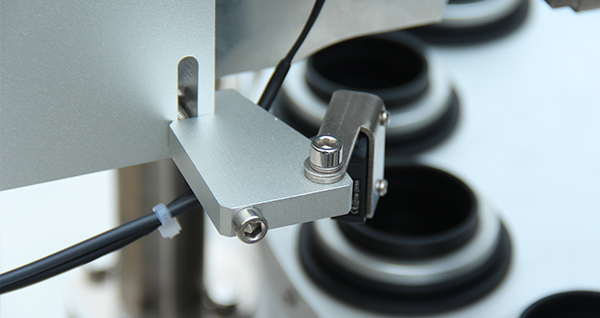

· Auto tracking system

With ability to track and adjust the frequency of ultrasonic wave, we ensure every stable sealing result.

About Us

Known as Utien Pack, Utien Pack Co,. Ltd. is a technical enterprise aiming at developing highly automated packaging line. Founded in 1994, it is becoming a well-known brand through 20 years' development. Our current core products cover different industries such as food, chemistry, electronic, pharmaceuticals and household chemicals.

We have participated in the draft of 4 national standards of packing machine and achieved over 40 patent technologies. Our products are produced under ISO9001:2008 certification requirement to build high quality packaging machines and make a better life for everyone. We provide solutions to help you make a better package and a better future. Utien-Packing is always your trustworthy partner!

By continuing to use the site you agree to our privacy policy Terms and Conditions.