- WhatsApp: +86 13606526028

- Email: contact@utien.com

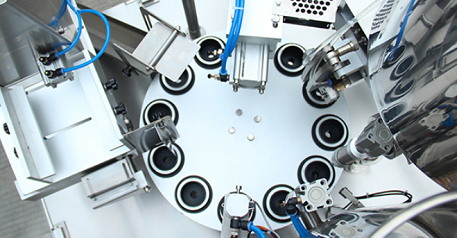

Ultrasonic sealing is a modern technology that employs the use of sound–mediated vibrations to release heat at a molecular phase inside the tube itself. These vibrations, generated from an anvil and sonotrode, agitate the molecules in the plastics so that they flow. Once the plastic becomes soft and starts melting, its parts are connected by a strong cohesive force to form perfectly-fit joints. After a short time of cooling under pressure, they form firmly joined molecules. This friction at the molecular level helps in the sealing of the product without the use of direct heat.

If you want to start enjoying the benefits of this technological innovation, there is a need to partner with a trusted and reliable ultrasonic tube sealing machine manufacturer.

Since the quality check is an integral part of good packaging processes and a goal for every packaging industry, it is ideal to know how ultrasonic tube sealing machine compares with heat tube sealing machine.

Let us discuss this under the following headings:

The sealing width created by Ultrasonic tube sealer is around 75% of that made by the Heat tube sealer.

Ultrasonic tube sealing machine with a smaller seal width usually provides less wastage of raw materials.

Another dimension to the seal width is the aesthetic appeal. Industries such as the snack industry always prefer the larger seal. Though, preferences depend on the brand.

In the bags per minute rates, heat tube sealing is more competitive. However, this rate can fluctuate depending on several factors such as product type. But all things being equal, the heat sealing process outclasses that of the ultrasonic technology.

Although ultrasonic technology is making great improvement in this aspect, heat seal technology is still most preferred in terms of BPM.

However, some clients note that the over throughput of their production yield has increased with the change to ultrasonic technology.

They pointed out some of the advantages of the ultrasonic tube sealing machine which are:

Short time to heat the jaws.

The jaws are not very hot once the productions run is over, thus making it safer for the operators.

Little or no concern about leakage for some products.

Research conducted has shown that ultrasonic tube sealing machine takes the forefront when it comes to lower energy consumption.

The energy consumption for the ultrasonic sealing machine is almost not dependent on the speed of the machine.

Energy utilization takes place during the sealing process only, except for some joules of energy consumed during the operation of the generator.

In short, Ultrasonic tube sealer is more competitive in the energy consumption.

The difference in the initial cost of purchase between ultrasonic tube sealing machine and heat tube sealing machine is wide.

However, the former begins to make up for its high cost with its lower energy utilization and minimal raw material usage.

The initial purchase can be a challenge, though, in the long run, ultrasonic tube filler will no doubt be a wise investment.

One of the advantages often seen to be associated with ultrasonic tube sealer is its ability to seal through products as well as being useful for products that are heat sensitive.

This ensures that it is suitable for products such as cream and liquids. Generally, the type of sealing technology depends solely on the product we want to use them for.

Yes, your choice of sealing technology largely depends on the products. However, to get a high-quality ultrasonic sealing technology, you need to partner with a reliable and trusted ultrasonic tube sealing machine manufacturer. Kindly click here to check and make your order from us today!

By continuing to use the site you agree to our privacy policy Terms and Conditions.