- WhatsApp: +86 13606526028

- Email: contact@utien.com

The medical field is a special niche that requires and uses a wide range of materials and products. One peculiarity of these materials is their packaging demands. When it comes to the packaging of medical products and materials, specific requirements have to be met.

According to the standards of the medical industry, sterile packaging is defined as a sterile barrier system. Such system is of high microbial barrier performance, protecting the products and maintaining the sterile environment with a certain period of time(marked validity period.

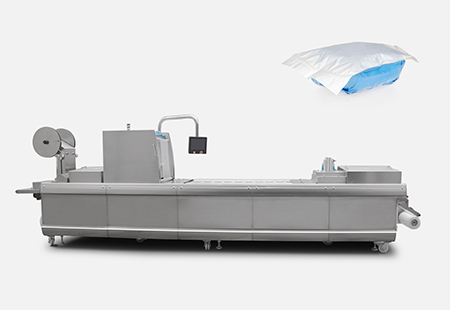

Now, when it comes to the medical packaging, a wide range of machine are employed. One of the most popular machines is stretch film packaging machine.

The unique properties of this packaging equipment is that it meets with the safety level required for medical products.

Let’s check below

1. Sterilize.

The stretch film packaging machine is designed to ensure that the product is sterilized. Sterilization can be achieved before and after the packaging process. It allows for some common sterilization procedures such as high-temperature steam, gamma-ray, ethylene oxide and more.

2. Protective barrier against microbes.

The integrity of the film provides a strong barrier against the intrusion of microorganisms. This means that the original state of the medical product such as tablets are maintained. In addition, environmental factors such as air and moist are barricaded.

3. Transparency.

The packaging material of products is quite important especially for customers who want to ensure quality by sight. Also, transparency helps to distinguish products and for easy selection.

4. Protection.

Apart from the protection against microorganisms, the need for protection against external pressure and collision is also important. The stretch packaging machine provides a film that keeps the medical product in good shape and texture during the shipping process.

5. Print information about the product.

For easy identification, the product packaging process should have some imprints. The packaging machine is designed to provide information about the product on the packaging film.

6. Ease of access to the product.

In order to minimize damage to the product, the sealing position must be obvious and easy for users to tear off. We mean by attention that we should avoid using sharp tools to tear the package to avoid damage or failure of the product.

With the rise of labor costs and the enhancement of environmental protection and safety awareness, the automation of packaging machinery has received increasing attention from medical companies. Nowadays, the introduction of stretch film packaging machines into the medical packaging industry is what the packaging industry needs to do most.

Utien Pack has been engaged in the packaging machinery industry for more than 20 years, and developed and produced fully automatic thermoforming stretch film packaging machines more than twenty years . It integrates thermoforming, filling, vacuum, heat sealing and slitting into one, automatic completion, reducing manual participation. The packaging materials are environmentally friendly and non-toxic and are also suitable for use in clean workshops.

We are here to provide you with your packaging solutions. Contact us today.

By continuing to use the site you agree to our privacy policy Terms and Conditions.